|

New Actuator Design

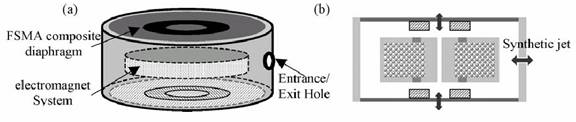

Summary An improved version of the membrane actuator has been designed and constructed based on our previous diaphragm actuator. It consists of ferromagnetic shape memory alloy composite (FSMA) diaphragm and an electromagnet system. The actuation mechanism of the membrane actuator is a hybrid mechanism. The high momentum airflow will be produced by the oscillation of the circular FSMA composite diaphragm driven by electromagnets close to its resonance frequency. This membrane actuator is designed for the active flow control technology on airplane wings. The active flow control (AFC) technology has been studied and shown that it can help aircraft improve aerodynamic performance and jet noise reduction. AFC can be achieved by a synthetic jet actuator injecting high momentum air into the airflow at the appropriate locations on aircraft wings. Due to large force and martensitic transformation on the FSMA composite diaphragm, the membrane actuator can produce 190 m/s synthetic jets at 220 Hz. A series connection of several membrane actuators is proposed to construct a synthetic jet actuator package for distributing synthetic jet flow along the wing span.

(a) Schematic of the membrane actuator (b) the synthetic jet flow created by the oscillation of the FSMA composite diaphragm

Related publications

Sponsored by NSF??

|