Flat Metasurface Alvarez Lens for Eyewear

Metasurface freeform optics: The function of an optical element is intrinsically tied to its geometry. While manufacturability has often constrained optical elements to have rotational invariance, the emerging field of freeform optics leverages more complex curvatures, often involving higher order polynomials of the spatial dimension, to enable novel functionalities and simplified compound optical systems. These elements have been shown to be capable of correcting aberrations, off-axis imaging, expanding field of view, and increasing depth of field. Recent interest in freeform optics has been driven by potential applications in near-eye displays as well as compact optical systems for medical, aerospace, and mobile devices where there are stringent constraints on the size and weight of the optical package. One surface of particular interest is the cubic profile, where the surface of the optical element is defined by a cubic function. These elements have been shown to exhibit increased depth of focus, and in tandem, they can form an aberration-correcting lens with adjustable focus called the Alvarez lens. Unlike conventional optics, metasurface optical design is curvature agnostic, readily accepting both conventional spherical curvatures as well as complex freeform surfaces with no additional design difficulties, while maintaining a thickness on the order of the optical wavelength. Moreover, well-developed semiconductor nanofabrication technology can be readily employed to fabricate such structures.

Metasurfaces are two-dimensional arrays of sub-wavelength scale scatterers arranged to arbitrarily control the wavefront of incident electromagnetic waves. Rather than relying upon gradual phase accumulation, metasurfaces impart an abrupt, spatially varying phase profile on the incident light. This allows us to map complex curvatures onto a flat, wavelength scale thick surface by converting them into a discretized spatial phase profile. In addition to their compact size and weight, metasurfaces are fabricated using a single step lithography procedure with mature, highly scalable nanofabrication technology developed by the semiconductor industry.

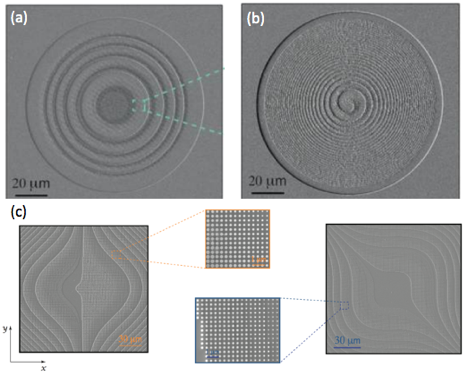

Figure: Different metasurface optical elements fabricated in our lab: (a) Lens; (b) Vortex beam generator and (c) cubic and Alvarez metasurfaces

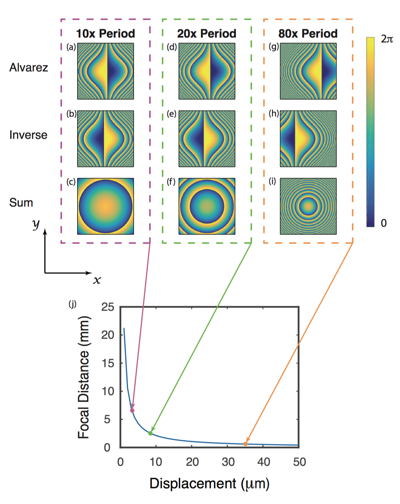

Alvarez Lens: Two cleverly designed cubic lenses, placed in front of each other

Figure: Operation of Alvarez lenses. Two cubic surfaces, when displaced laterally provide the phase profile of that of a lens, whose focal lengths change depending on the displacement.

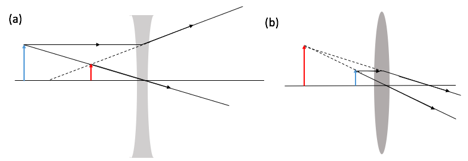

Image creation for objects placed at different distance: Depending on eye conditions, different focal length lenses (or optical power, which is inverse of the focal length) will be necessary, as shown here.

Figure: Depending on the object distances, different focal lengths are required to create the image.